With the rapid growth of consumer electronics and mobile phone markets, the performance of mini lens has become more challenging compared to many years ago. However, manufacturing costs, packaging, and imaging quality of mini lens pose unique challenges to optical designers.

TeSoo has been providing the most sophisticated micro-optical component manufacturing services as well as the optical design and assembly of precision micro-imaging equipment for the scientific, commercial, medical and sensory technology markets. TeSoo is capable of meeting the most challenging specifications and tolerances. Our mini lens manufacturing capabilities ensure that our customers' products have a diameter of 3mm, a center thickness of 0.8mm, and a surface accuracy of 1/4λ.

All of our miniature lenses including surgical lenses are custom-made, please talk to our engineers about your own microsystem requirements and learn how we can help you.

Types Of Mini Lens

What Is Mini Lens?

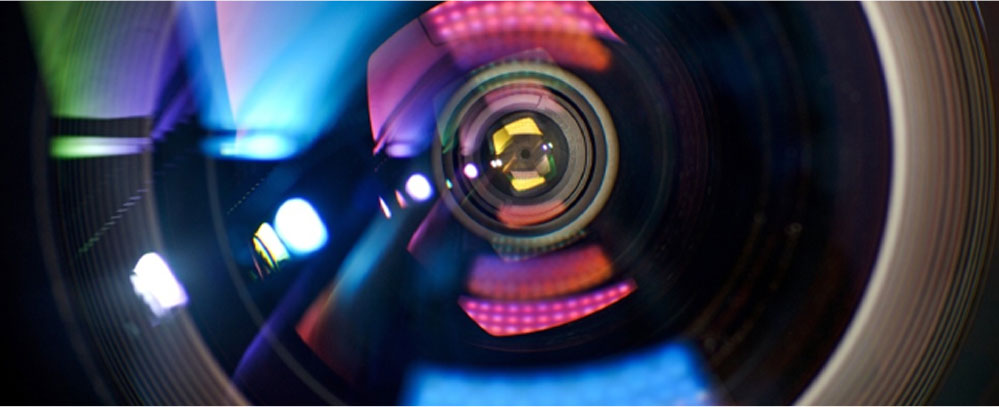

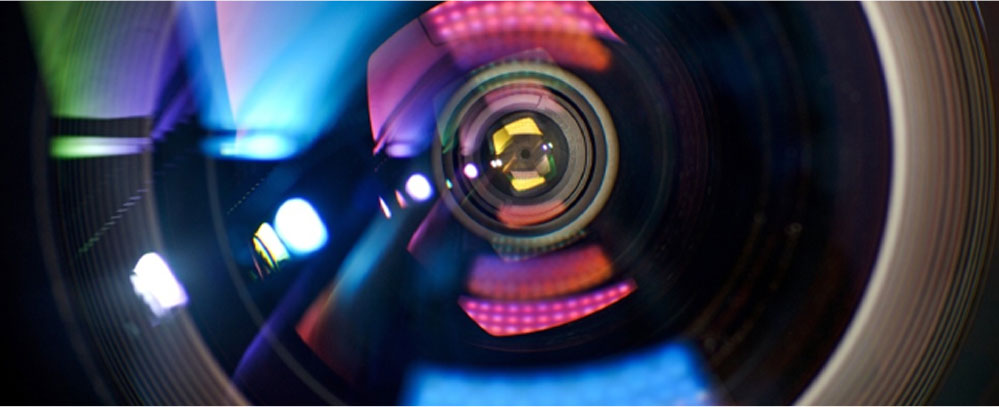

Mini lenses such as the M9 lens are tiny optical components that can manipulate electromagnetic waves (light) like traditional lenses, but they are thinner than a normal lens. Due to its small size, ease of large-scale manufacturing, high production cost-effectiveness, and the potential to revolutionize a variety of optical applications, this technology has excited developers in many industries. Compared to traditional lenses, the concept of a mini lens is a single thin and flat structure with multiple waveguides (looks like tiny pillars) arranged in a specific pattern. These pillars are also likened to antennas. They are nano-elements made of titanium dioxide (TiO2) with a length of about 600 nanometers (nm), which is shorter than the length of 10 hydrogen atoms placed side by side.

English

English